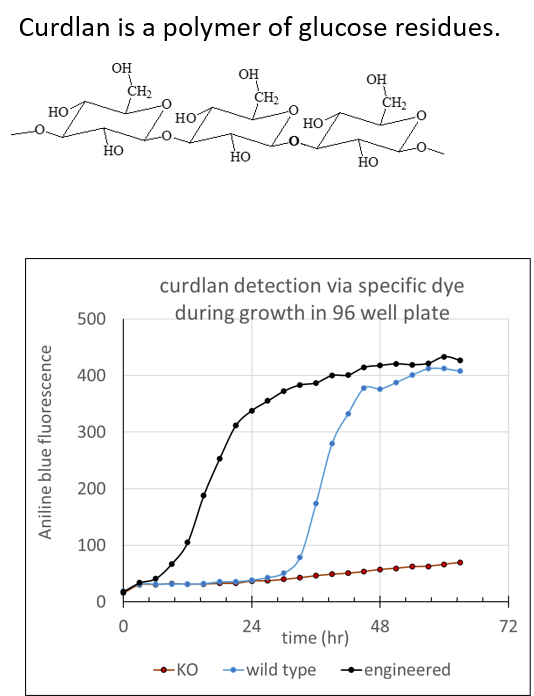

The exopolysaccharide curdlan is useful in industry (e.g. pharmaceuticals, foods, bioplastics, building material). But why do certain microbes produce it? How does it help survival? Such knowledge might be useful to the goal of encouraging the bacteria to produce even more curdlan, or lowering the cost of production.

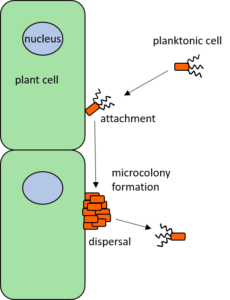

This scheme shows the bacterium, Agrobacterium tumefaciens, in its native setting. A. tumefaciens is a well known plant pathogen that causes growth on a variety of plants. As part of its normal attempt to survive, the bacterium forms a microcolony on the surface of the plant tissue. Curdlan is one of the molecules produced by the bacterium that is important for holding the cells together, a sort of sticky glue.

Recently, I discovered another use for curdlan, one that was quite unexpected.

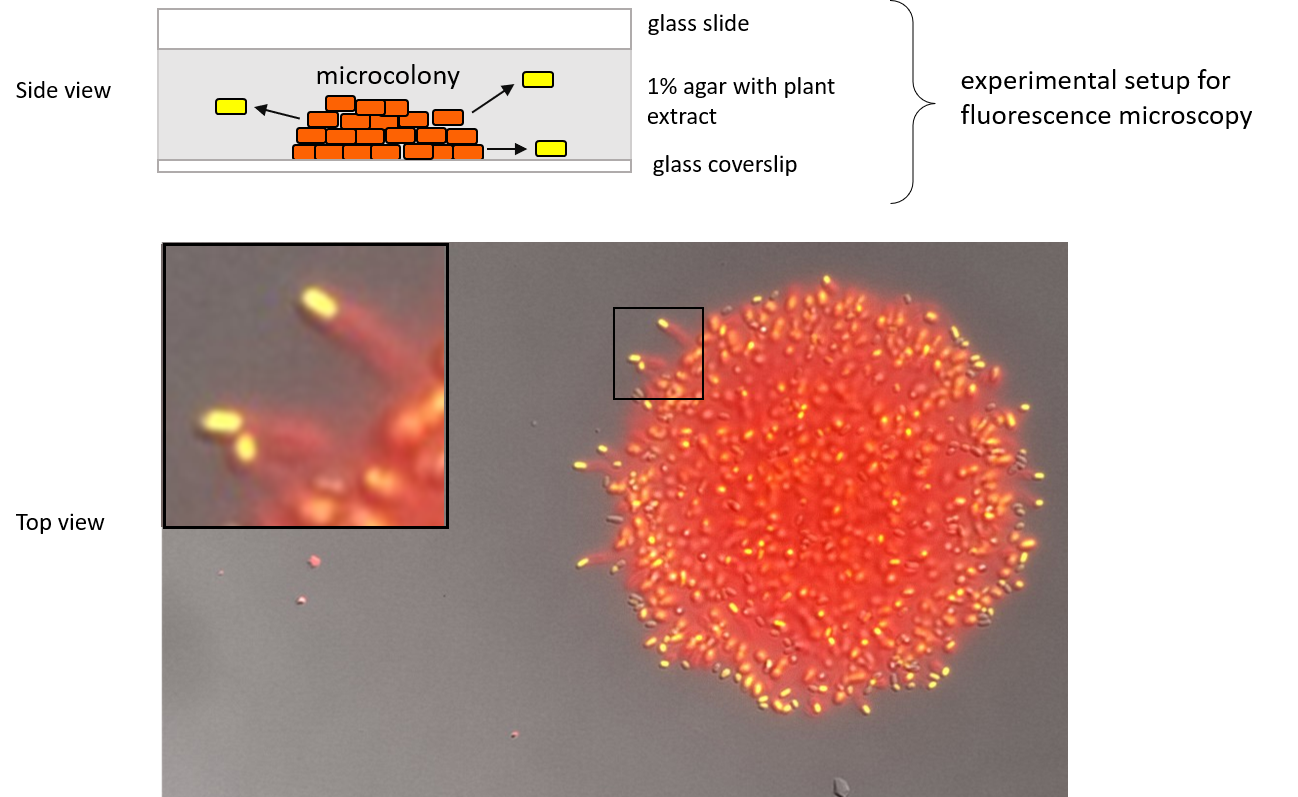

First, the A. tumefaciens cells were modified genetically to carry a reporter, a special protein that gives cells a bright yellow colour. The goal of the reporter is to mark only those cells that are actively producing curdlan.

Next, the cells were placed in a gel (1% agar) which contains all the nutrients (e.g., glucose) they need for optimal growth. On the upper and lower side of the gel is glass, forming an effective barrier (preventing dehydration) and allowing microscopic examinations. This environment allows single isolated cells to grow into microcolonies of thousands of cells.

Included in the gel is a dye called Aniline blue. The purpose of adding Aniline blue is to be able to see the curdlan. This dye binds only to curdlan, and gives off a red fluorescence under UV light. With this stain, it is possible to see (in high resolution photos) that curdlan is produced as a capsule, a layer that covers the entire cell body.

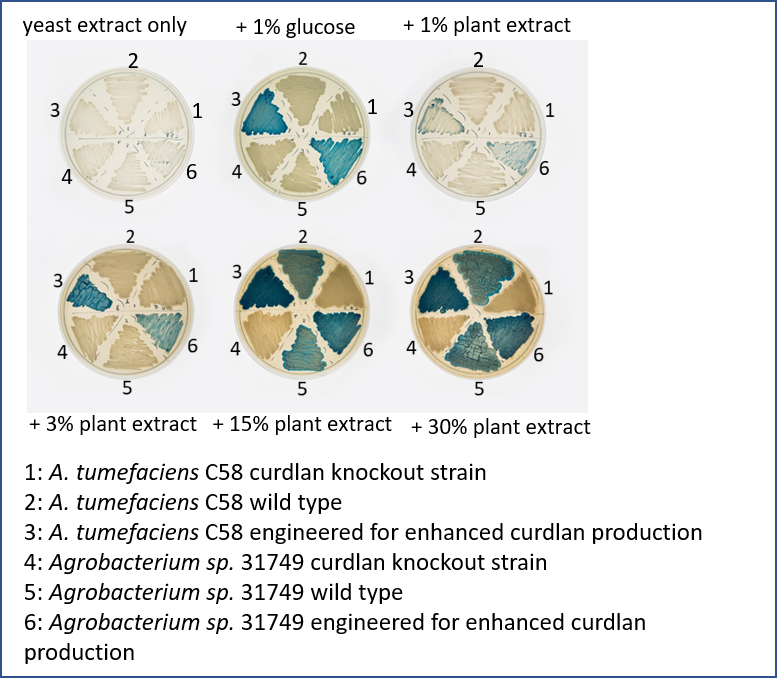

Does A. tumefaciens produce curdlan when grown on plant extracts? When produced for industry in large fermentors, the industrial strain (Agrobacterium sp. 31749) is fed with a mixture of salts and sugars (e.g., glucose). As mentioned above, Aniline blue is an excellent indicator of curdlan production. It can be added to any growth medium. Under normal light, Aniline blue shows up intensly blue in the presence of curdlan.

Growth on these plates shows that a variety of Agrobacterium strains, both the wild type (C58) as well as the industrial strain (31749) actually prefer to produce curdlan from plant extract rather than from glucose. These results provide support for the idea that curdlan is produced under natural conditions, i.e., during microcolony formations on the surface of plant tissue.

This result also shows another important point. Through genetic modification of the regulation of curdlan production, the cells can be ‘fixed’ to produce more curdlan, and that from a potentially cheaper source — crude plant extracts. This finding has excellent commercial potential.

Global demand for curdlan, for example, in various food products such as snack foods is growing. Although high in energy (a polymer of up to 500 glucose units), curdlan cannot be digested in the human gut. Therefore it contributes to the dietary fiber. The advantage in adding it to various foods (typically at about 1-2%) is that it creates a creamy feel in the mouth, is tasteless, and extends the shelf-life of various foods (typically by preventing oxidation and desiccation).

The genetically modified strains that I have developed in the lab have improved production rates and require shorter fermentation times. They also have the advantage of being less selective with their food, meaning that they can use a much greater variety of foods to produce curdlan.

Important points:

- Curdlan is a linear, unbranched polymer of glucose residues extending up to 500 units.

- Aniline blue is a dye that specifically binds to curdlan.

- Curdlan production is enhanced during growth on plant extract.

What is the role of curdlan in the Agrobacterium lifestyle?

New observation: production and deposition of curdlan as a capsule allows some cells to escape from the microcolony by shedding their curdlan capsule – like rocketeers.